Hey, what is this? It looks like frozen smoke.

This is not smoke, but a solid, to be precise, aerogel, the lightest solid in the world.

What is aerogel? First of all, let's understand the "gel".

The polymer solution or sol of a certain concentration, under appropriate conditions, the viscosity gradually increases, and finally loses its fluidity, the entire system becomes an elastic semi-solid with a uniform appearance and maintains a certain shape. This elastic semi-solid is called coagulation glue.

Jelly is the first kind of gel recognized by scientists. This gel is formed after being filled with water or other liquids. Some gels are formed after being filled with gas. This is called "aerogel".

In 1931, American scientist Samuel Stephens Kistler prepared this new material, named "aerogel", aerogel. "Aero" + "gel" vividly depicts the characteristics of this new material, namely a gel filled with gas.

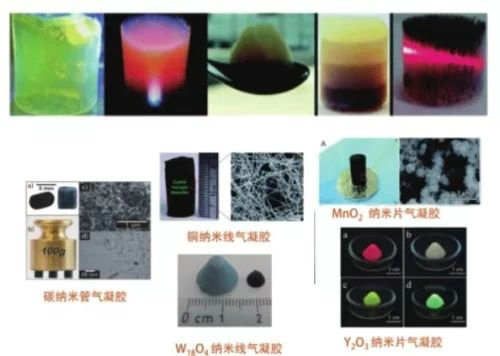

Compared with ordinary porous materials, aerogel has an important feature: its skeleton is at the nanometer scale. Therefore, when the visible light passes through, it scatters less and looks like "frozen smoke."

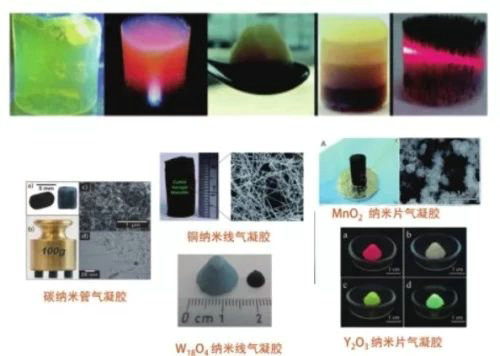

Aerogels have extremely low density and are the lightest solid in the world. At present, the lightest aerogel is a "full carbon aerogel" with a density of only 0.16 mg/cm3 (excluding air density), which is only 1/6 of the air density. Putting this material on the flowers, the soft stamens hardly deformed.

The preparation process of aerogel is divided into two steps: 1. Preparation of wet gel; 2. Drying of wet gel by special techniques. The most traditional preparation method of wet gel is the sol-gel method. Disperse the compound containing highly chemically active components in a solvent, and form a reactive monomer through a hydrolysis reaction. The reactive monomer polymerizes to form a sol, which in turn generates a gel with a certain spatial structure. The gel produced at this time is a bit similar to the jelly we usually eat, followed by further drying the jelly-like gel to obtain an aerogel. Due to the effect of surface tension, under normal conditions, the volatilization of the liquid in the gel will cause the weak skeleton of the gel to collapse. Drying by freeze drying technology can solve this problem. The wet gel was frozen at low temperature and then dried under vacuum. Because the freezing process has turned the liquid in the gel into a solid, and then detached from the gel skeleton in the form of sublimation in a vacuum environment, this can avoid the collapse of the skeleton caused by the volatilization of the liquid, and obtain the aerogel we expect.

"What's the use of aerogel?" I believe everyone will have such questions. The answer will be various, "It has extremely low thermal conductivity and can be used as a super thermal insulation material" "It can be used as an electrode"...

In general, the performance of aerogel is mainly contributed by two parts: one part is the structure, which is simply the performance derived from the porous nature, such as excellent thermal insulation performance. A flame is used to heat a flower through the aerogel, and the flower has almost no damage. In addition, some aerogels also exhibit excellent adsorption properties, such as "carbon sponge".

Another part of the performance comes from the fact that the components that make up the skeleton of the aerogel are at the nanoscale. Some properties of nano-scale particles themselves are often enhanced when they exist in the form of aerogels. For example, the electrode material of lithium batteries-manganese dioxide (MnO2), when it exists in the form of aerogel, the discharge performance of lithium batteries has been greatly improved.

As a material born in the early 20th century, aerogel was not a recently discovered "new material", but its excellent characteristics in various aspects have attracted widespread attention. The application of this material needs to be continuously researched and explored. .

Copyright © Jiangxi Hongge Technology Co., Ltd. Gan ICP No. 18012040-2 Contact: Mr. Yu Tel: 13755566733

Address: Xinyu High-tech Development Zone Industrial Real Estate Phase III (Dongxing Road No. 1988) 2nd Floor, Zone A, Nine Building Technical Support: