For a long time, the die as the core component of the coating machine has been controlled by Japanese companies including Mitsubishi, which has become a key factor restricting the cost reduction of domestic coating machines.

"Xuhesheng's coating die is very close to Mitsubishi's products in accuracy, but the price is only about half of it."

On September 27, at the 2014 High-Tech Lithium Battery Expo, Peng Jianlin, general manager of Shenzhen Xuhesheng Technology Co., Ltd. (hereinafter referred to as "Xuhesheng"), said that the performance of domestic coating die is approaching traditional international enterprises in performance. Prices and services have become powerful weapons for these domestic companies to seize the market.

With the gradual decline in the profitability of lithium battery products, battery companies have to work hard on cost control. Products with price advantages have become one of the deciding factors for companies to buy coating machines. Gaogong Lithium Battery Industry Research Institute (GBII) believes that in the next 5 years, the improvement of system automation and the localization of core components will be the two main lines of the development of coating machines.

As a company that focuses on the research and development of coating die heads, this company, which was established more than a year ago, is committed to promoting the localization of lithium battery equipment.

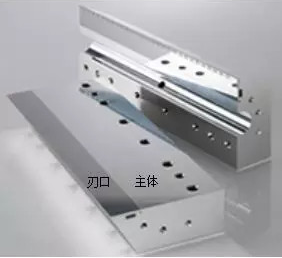

It is understood that Mitsubishi's die head can be guaranteed to be below 5 microns, and the actual detection is 1-3 microns. Xu Hesheng's die head can be controlled within 3 microns. In addition, Peng Jianlin introduced that the Slotdie coating die product developed by his company has mature technology in ultra-thin coatings. The thinnest coating currently can be as low as 0.1 microns. In the lithium-ion battery industry, it has been successfully applied to separator surface coatings, The conductive coating on the surface of aluminum foil is a difference from Mitsubishi's product range in China.

In Peng Jianlin's view, after-sales service is a more prominent highlight of its products.

As a team with technology precipitation, we not only respond promptly after sales, but also ensure that our customers' products are done well.

According to him, most of the imported coating die heads currently only sell products to equipment companies, and do not care about direct application customers. In this way, the requirements for coating products of battery cell manufacturers are largely passed on to equipment manufacturers, which is also an important technical threshold for many coating equipment manufacturers.

In fact, the development of SlotDie coating die is a complicated process. From the perspective of the development process abroad, professional coating die manufacturers can solve problems more accurately. In Europe, North America, Japan, South Korea and other places, almost all exceptions are provided by professional coating die manufacturers.

Peng Jianlin said that Xuhesheng's products have been used in several well-known battery companies in China because of persistent research and development and customer service. "Customers are satisfied with the accuracy and function of the product, and sales in the second half of the year are expected to make a major breakthrough."

Copyright © Jiangxi Hongge Technology Co., Ltd. Gan ICP No. 18012040-2 Contact: Mr. Yu Tel: 13755566733

Address: Xinyu High-tech Development Zone Industrial Real Estate Phase III (Dongxing Road No. 1988) 2nd Floor, Zone A, Nine Building Technical Support: