Slot extrusion coating technology is an advanced predictive coating technology, which can obtain a higher precision coating. At present, the lithium ion power battery industry has generally adopted slit extrusion coating technology to manufacture battery pole pieces.

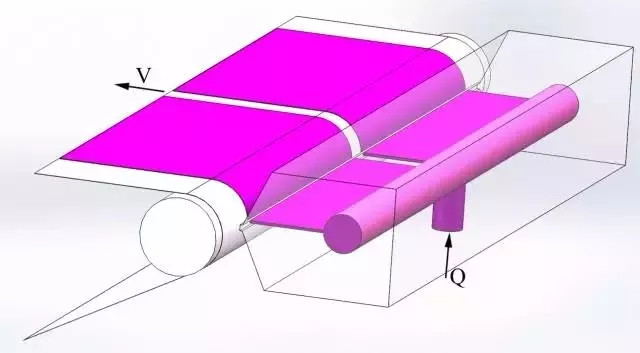

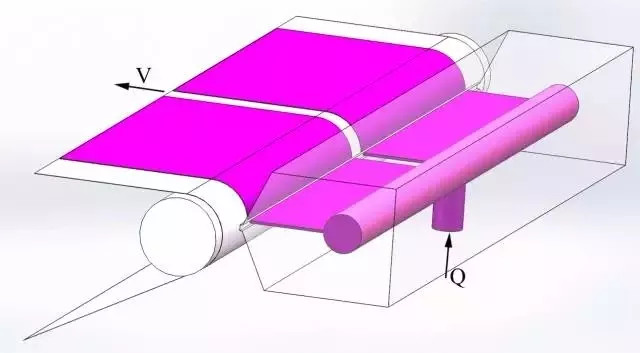

The schematic diagram of slot extrusion coating is shown in Figure 1. A certain flow of slurry enters the internal cavity of the die from the material port of the extrusion head and forms a stable pressure. The slurry is finally ejected at the slit exit of the die , Coated on foil.

Figure 1 Schematic diagram of slot extrusion coating

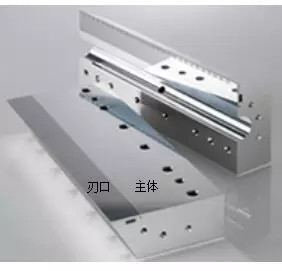

Extrusion die head is a key part of lithium battery coating, which directly determines the quality and uniformity of the coated pole piece. Therefore, the die cost is generally greater than 30% of the entire coating machine. The coating die head structure mainly includes an upper die, a lower die and a gasket. The lower film has a special cavity, the upper mold is relatively simple, and the gasket is located between the upper and lower molds according to different coating forms, as shown in Figure 2. The factors that affect the uniformity of the coating thickness mainly include the uniformity of the exit speed of the extrusion die cavity, the flatness of the substrate, the uniformity of the slurry, and the surface tension, etc., wherein the uniformity of the exit speed of the extrusion die is the main One of the factors. The geometric structure of the extrusion die cavity directly affects the flow field shape of the cavity, and optimizing the structural parameters can effectively improve the uniformity of the outlet velocity distribution. At present, many domestic companies have independently developed and designed coating die. The design optimization includes:

(1) The design of the inner flow channel of the coating die, such as gradient, hanger, single cavity and double cavity, etc. The goal is to maintain the flow rate of the coating liquid in the mold, without causing problems such as static areas or sedimentation, so as to ensure that the exit speed of the slit of the die head is uniform to ensure the uniformity of the coating. (I will write a detailed summary later)

(2) The optimal design of the feeding position, such as the lower feeding of the die head and the side feeding of the die head, etc., change the fluid flow state to ensure that the slit exit speed of the die head is uniform.

(3) Optimized design of gasket structure.

Figure 2 extrusion coating die

Among them, the cutting edge of the coating die is the key to the entire die. As shown in Figure 2, the slurry continuously flows through the cutting edge and sprays from the slit during coating. The performance index of the cutting edge will directly affect the coating Cloth effect. According to the characteristics of lithium ion battery coating, the edge of the extrusion die should meet the following requirements:

(1) The precision of cutting edge size is high. The general thickness of lithium ion battery coating slurry is 100-300 μm, and the accuracy requirement is <1%. Therefore, the size of the cutting edge is also very high. For example, the cutting edge requires sharpness to achieve micron-level accuracy; the straightness of the cutting edge is high ( Less than 2μm/m).

(2) The surface of the nozzle surface is smooth and the roughness is small (Rz0.2μm or less). The slurry is a suspension of active material particles, which flows through the edge and is then ejected from the slit. If the solid stays and accumulates somewhere, it will cause uneven coating thickness and the formation of vertical stripes and other defects. This requires that the surface of the nozzle surface is smooth and the roughness is small, and it does not cause clogging of solid particles.

(3) The cutting edge material has high hardness, wear resistance and long service life. The positive and negative electrode slurry is a suspension composed of solid particles. During the coating process, the slurry is continuously sprayed from the blade slit under the pressure, and the solid particles will form abrasive wear on the spray surface of the blade. It is required that the cutting edge material has high hardness and wear resistance, and can be used for a long time.

(4) Corrosion resistance. Lithium-ion battery slurry often contains organic solvents, polymer binders and other components, and the cathode slurry is often weakly alkaline. Therefore, the cutting edge is required to resist corrosion.

(4) The cutting edge is sharp, which requires a certain toughness, no fracture, high compressive strength and bending strength, and no bending deformation.

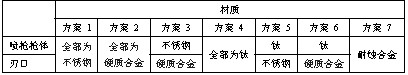

Taking into account the specific use environment and cost factors, we should choose the material of the extrusion die according to the needs. As shown in Table 1, these different material combinations can be considered.

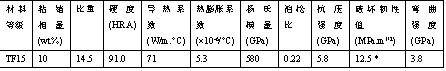

Table 1 Extrusion die material selection scheme

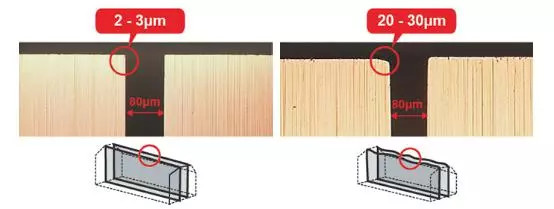

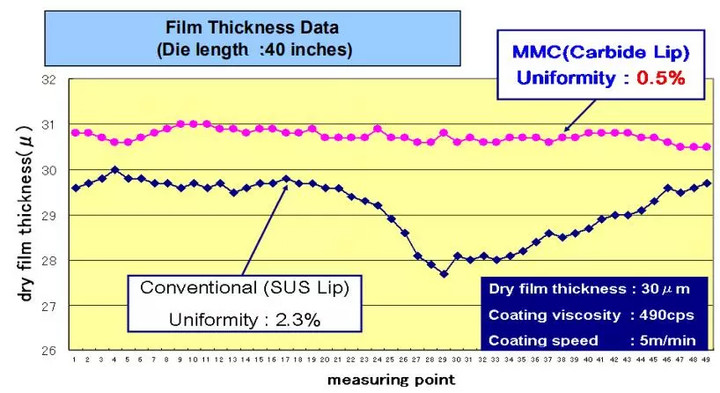

Cemented carbide is a powder metallurgy product mainly composed of hard phase and binder phase. The hard phase is very hard, mainly various carbides, and the main carbides are: tungsten carbide (WC), titanium carbide, tantalum carbide and niobium carbide, and cobalt is used as the binder phase. Japan's TF15 is a tungsten steel cemented carbide. The grain size of this material is small, less than 1μm, taking into account the hardness and toughness, it is easy to form a sharp edge, and the strength of the blade tip is high. See Table 2 for its basic performance parameters. Figure 3 is a comparison of the precision of the cemented carbide cutting edge and the stainless steel cutting edge. The two different cutting edge materials are used for coating accordingly, and the coating thickness uniformity is also different, as shown in Figure 4. The cutting edge is made of hard alloy with excellent wear resistance, which can achieve long life and high quality.

Table 2 Basic performance parameters of TF15 material

Figure 3 Comparison of cemented carbide cutting edge and stainless steel cutting edge

Figure 4 Comparison of coating thickness uniformity of tungsten carbide carbide and stainless steel blade die

To produce high-quality batteries requires high-precision equipment, and equipment development also needs continuous improvement. In the above summary, please correct me.

Copyright © Jiangxi Hongge Technology Co., Ltd. Gan ICP No. 18012040-2 Contact: Mr. Yu Tel: 13755566733

Address: Xinyu High-tech Development Zone Industrial Real Estate Phase III (Dongxing Road No. 1988) 2nd Floor, Zone A, Nine Building Technical Support: